Plastisol

Plastisol is a dispersion of PVC resin and other key ingredients into a plasticizer to produce a fluid mixture that ranges in viscosity from very thin to a heavy paste.

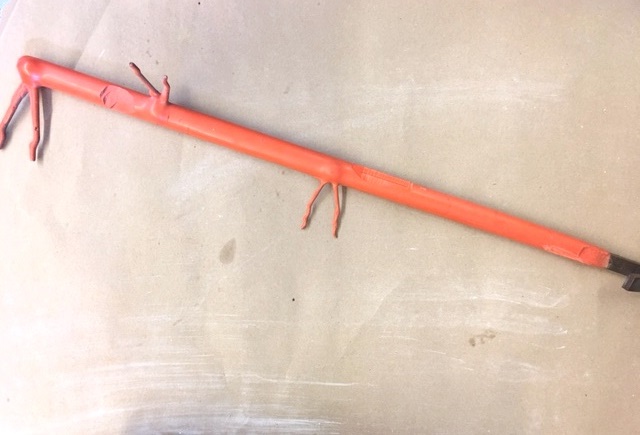

In the dip coating process a heated metal part is dipped into the plastisol for a set amount of time. The longer the part is in the plastisol the thicker the coating becomes. After the part is removed from the dip tank it goes into an oven so it can finish the fusion process. Typically plastisol will fuse between 320°-350° F.

*Upon request our plastisol can be formulated to be phthalate free, meeting REACH Directives or any specifications the customer requires.

Applications: Medical, tools, office supplies, filters, drapes, shower curtains, dog collars, shoes, Inks, Paints.

As a leading manufacturer of custom plastisol, Miltec has the technological experience and production capacity to serve all of your needs.

Please contact Miltec to discuss your application