Molding Compounds

Molding Compounds – A compound used to make a shape. A ready-made composite where the reinforcement and matrix have already been combined and shipped in bulk.

Plastisol has 3 types:

Rotational Molding – Plastisol can be rotational molding which involves a heated mold containing material rotated to disperse material so it conforms to inner mold surface.

Slush Molding – when the material is placed in a hollow mold and is heated until gelled. Once it is gelled the excess material is removed by inverting mold. Then the mold is heated again until plastisol is fused.

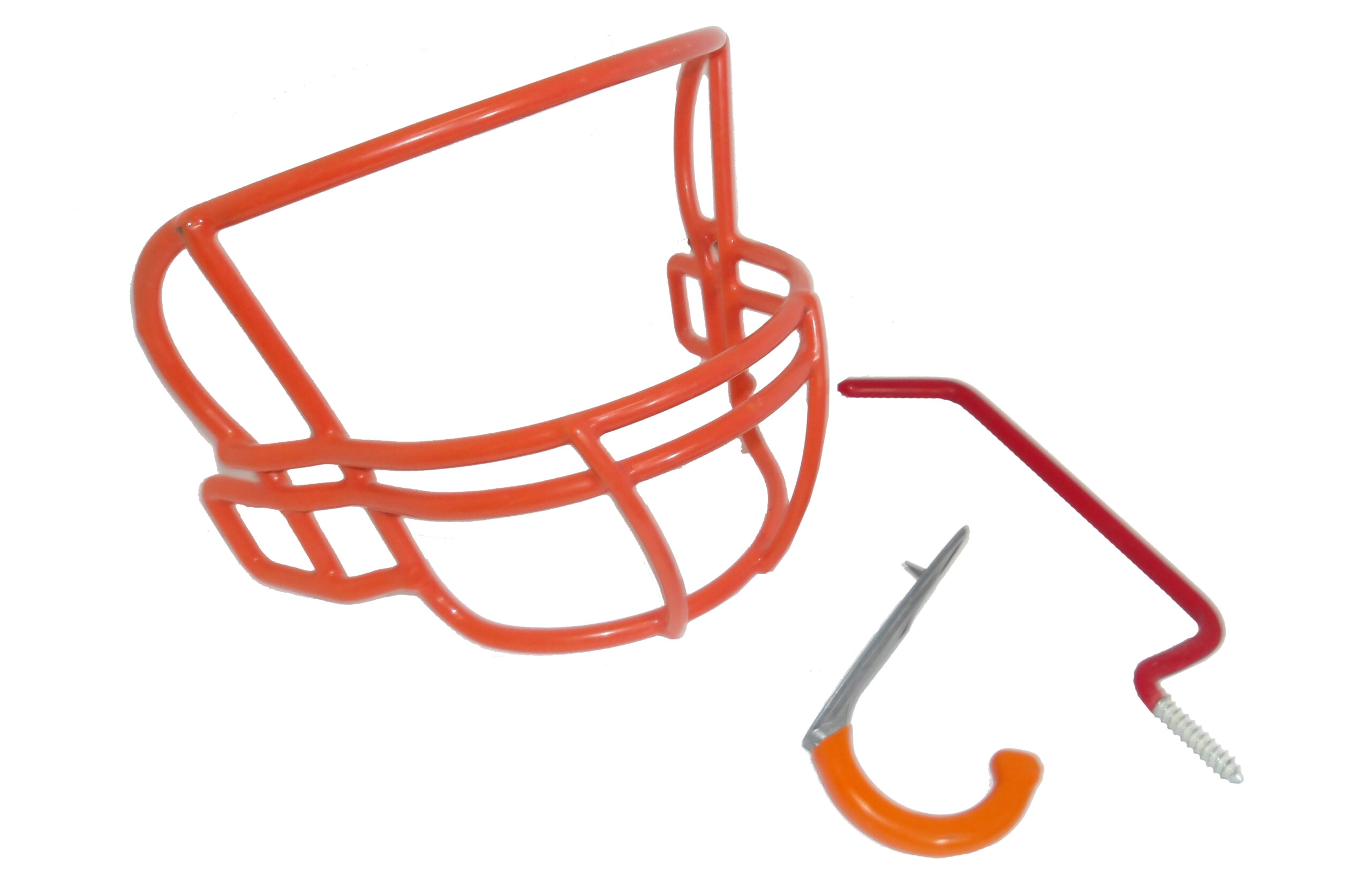

Dip Molding – A metal part is heated then dipped into the plastisol. After dipping the part goes back into the oven so fusion can occur. Once the part comes out of the oven the part is removed from the mold.

Applications: Dip molding, wire racks, tools, paper clips, vaults, caskets, springs, screening.

As a leading manufacturer of custom molding compounds, Miltec has the technological experience and production capacity to serve all of your needs. Please contact Miltec to discuss your application.